Digital Product Passports (DPP) are part of the European Commission’s Ecodesign for Sustainable Products Regulation that is being adopted across industries within different timelines. The regulations require that product information related to sustainability be made available to key stakeholders including the producers and distributors of raw materials and ingredients but ultimately to end-customers.

Digital Product Passports (DPP): EU product labeling regulations

Digital Product Passports are part of several new regulations issued by the European Commission for gathering and sharing data on products and their supply chains.

There are several, interrelated sustainability initiatives and regulations. The most important among these include the Circular Economy Action Plan (CEAP) and the Ecodesign for Sustainable Products Regulation.

What is a Digital Product Passport?

A Digital Product Passport refers to a digital profile given to an individual product which includes information such as its origins and supply chain history, sustainability of production, authenticity, and other business information such as warranty registration.

The goal of the E.U. in requiring Digital Product Passports is to provide transparency and traceability of products through their value chain, and for this transparency to aid in the E.U.’s transition to a circular economy.

Each physical product – for example, an article of clothing, a car battery – would have it’s own unique Digital Product Passport with information that is associated to it at the batch and unit level. A passport identifies a product uniquely, even if there are millions of similar products.

Supply chains are complex and there are often significant differences between one batch of goods to another. With unique identification down to the unit level made possible by a Digital Product Passport, it becomes more feasible for regulators to ensure that all goods being sold in the E.U. comply with forthcoming regulations related to a circular economy and sustainability.

Benefits of implementing Digital Product Passports

According to the Proposal for Ecodesign for Sustainable Products Regulation, The Implementation of Digital Product Passports is designed to increase:

-

Product sustainability

- Digital Product Passports accelerate the move to a more sustainable economy by supporting to extend product lifetimes and optimizing sustainability of products used.

- New markets in the area of sustainability are unlocked: recyclers can assess the real value of a product at the end of its lifecycle and more accurately calculate a fair price.

-

Information transparency

- With the information of products being available for all stakeholders to see, consumers can make more educated buying decisions, as more information is transparently provided and products become more comparable.

- Digital Product Passports are an easy way for regulators to check if a company has correctly implemented requirements, offering a more transparent view on the product at hand.

Who will need to implement Digital Product Passports?

Based on the first working plan released on April 15, 2025 – ahead of the April 19 deadline – the first industries required to comply are:

- Textiles/apparel (compliance ties in with the French Anti-Waste for Circular Economy Law (AGEC) that went into effect in January 2023).

- Furniture

- Tyres/tires

- Mattresses

Based on the CEAP’s first working plan, the first Digital Product Passports to be introduced in the E.U. will be in the following industries:

- Textiles/apparel (final product)

- Furniture (final product)

- Tyres/tires (final product)

- Mattresses (final product)

- Iron & steel (intermediate product)

- Aluminium/aluminum (intermediate product)

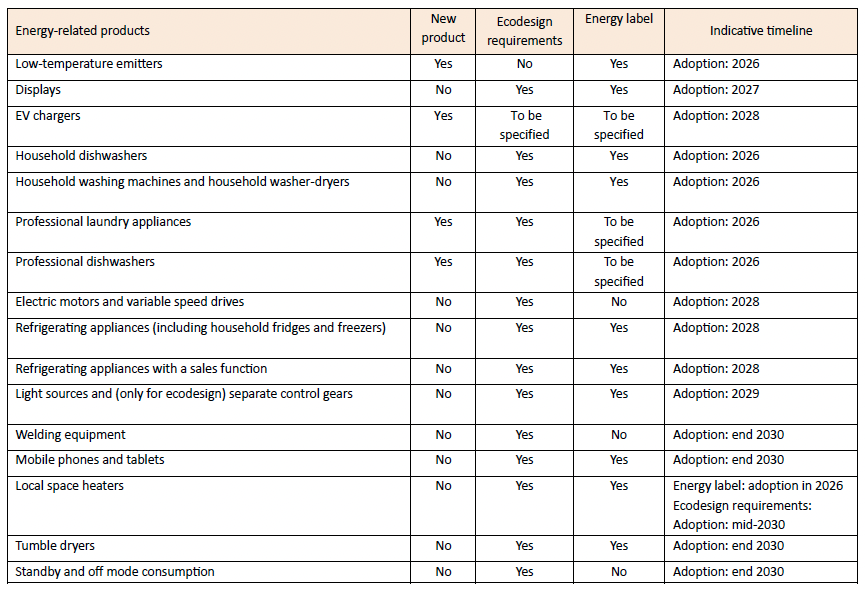

There will also be two legal acts setting horizontal requirements for repairability/reparability, recycled content and recyclability of electrical and electronic equipment. The following electronic items also form part of the first working plan:

Other industries will see Digital Product Passport regulation emerging as part of the 2025-2030 working plan.

See this list of industries and related E.U. Digital Product Passport regulations (November 22nd, 2022):

| Regulation | Key dates | Industries affected |

|---|---|---|

| EU strategy for sustainable and circular Textiles | The first working plan released in April 2025 specified apparel and shoes as the highest priority. Timeline specified is 2027 for adoption. | Textiles |

| Construction Products Regulation | Dates forthcoming with carbon emission statements already required for some construction materials. | Construction |

| EU proposed Ecodesign for Sustainable Products Regulation | Umbrella regulation with the first working plan, including product type priorities, released in April 2025. | Consumer products (CPG) |

| Corporate Sustainability Reporting Directive | Implementation details released in 2024. | Essentially, ALL Businesses |

| New EU Battery Regulation | Implementation is planned for 2026 | Battery manufacturers |

| Toy Safety Regulation | Dates forthcoming. | Toys |

| French AGEC Law | First companies need to be compliant by 1st January 2023 | Fashion, home textiles, apparel, electronics, toys and many others |

While Implementing Digital Product Passports will not be mandatory for EV and industrial battery producers until 2026, some are already opting for traceability options similar to Digital Product Passports. One example is VARTA®, who use unique QR codes on their automotive batteries to improve product traceability and create a direct engagement channel with the end users of automotive batteries.

What information needs to be on a Digital Product Passport?

Key requirements for Digital Product Passports include:

- Traceability of Materials – information on sources of raw materials, including environmental and social impact data, must be documented.

- Product Lifecycle Data – records of all lifecycle stages: manufacturing, shipping, sale, maintenance, repair, reuse, recycling, and disposal.

- Environmental Impact Reporting – tracking carbon footprints and other environmental impact metrics, especially for products like batteries.

- Consumer Information – providing consumers with information about product longevity, repair options, and environmental impacts.

How to implement a Digital Product Passport for your business

While we wait for clearer requirements to emerge, there is much that companies can begin to do to prepare for implementation of a Digital Product Passport.

There are two main implementation questions which are already relevant given where the regulation is headed:

- What is a suitable data model for your products?

- What is the right data carrier for public disclosure of your product information?

A four step process to implement a data model for Digital Product Passports

In most cases, companies have many things in place to be able to implement Digital Product Passports to their operations already today.

The implementation strategy for the data model of a DPP can be broken down into answering four questions:

- What data needs to be collected?

- Where is the data generated?

- How can the data be collected?

- Where does the data get stored?

Though (1) will continue to be clarified for different industries by forthcoming regulation, (2) and (3) above present the biggest challenge for those seeking compliance because not all information that is needed in the Digital Product Passport is collected today.

For example, ingredient or material tracking; tracking the end-to-end origin of materials is not mandatory today, and therefore many companies have no data collection channel to achieve that. Companies will have to start collecting and storing these data sets to be in compliance with the Digital Product Passport regulations.

Step 1: What data needs to be collected?

By evaluating the data requirements for your industry against the below data model, you can begin to map out an implementation plan. There are three categories of data that can be collected for and stored in a Digital Product Passport:

- Material traceability data – data on the supply chain or value chain, or product ingredients/ raw material and inputs

- Sustainability data – data on how sustainable the production process and distribution of the product is.

- Product-specific data – traditional product information, such as name, make, model, brand, etc.

Each of the above can be further split into dynamic data (batch or unit level), or static data (ie, SKU).

Dynamic product information refers to unit or batch specific information that is is different from one product to the next, for example date of production, or lifecycle information.

Static product information refers to product information that should not be different from one product unit to the next, like a product’s name, make, model, brand, size, weight.

Categories of data and examples of static, dynamic data for each

| Material traceability data | Sustainability data | Product-specific data | |

|---|---|---|---|

| Description | Data on supply chain, value chain, and material sourcing | Related to recyclability & Carbon footprint | Data regarding a specific article and/or product unit |

| Dynamic data example | Material country of origin | Product lifecycle stage (in the context of recyclability) | Production date |

| Static data example | Information about the product’s production process | General recyclability guidelines | Product name |

The requirements for specific material traceability, sustainability and product-specific data (both static and dynamic) are expected to vary from one industry to the next.

Step 2: Where is the data generated?

Once the data to be collected and disclosed has been established, the next step is to identify where this data is or can be generated.

Most companies already have tools that generate part of the data required for Digital Product Passports. The most common scenarios that data is generated are:

- At your or your supplier’s production sites, e.g. in manufacturing execution systems, local servers and applications.

- In your ERP or product information or lifecycle management systems.

- On excel files that are being maintained on a company internal level.

- The data is generated, but not stored anywhere.

Different data sets require data to be generated differently. For example, material traceability information will most likely be generated at production sites by your suppliers, while product specific information like article name will likely be generated and maintained in ERP or product information management systems.

Having a clear mapping of where the data required for compliance is generated is crucial to proceed to step 3.

Step 3: How can the data be collected?

Once you have mapped out if and where the data is generated, the next step is to identify how the data can be collected.

For each of the types data you intend to integrate into your Digital Product Passport, you can evaluate the feasibility of the following:

- Automated integration and data exchange via APIs

- Manual collection via Excel and CSV files

- Manual collection via mobile applications

- Pre-upload of static information that is already known about a product

When it comes to static information, data collection is relatively simple and straightforward. This data can be pre-uploaded, as these data points are already known, and are likely not going to change; for example:, a product’s name.

However, dynamic data which is different from one product unit to the next must be constantly collected. An example of this is date of production or the provenance of a material. For this kind of dynamic data collection, usually process changes for operations or investment into automation solutions are required. Depending on the digital maturity of a company’s operations the dynamic information can be collected fully automated via APIs or manually via CSV or Excel uploads or mobile apps.

From Scantrust’s experience, the answer is usually a blended mix of all the above data collection methods: some regions or SKUs have more advanced digital maturity and data can automatically be pulled via APIs, whereas some other regions or SKUs may need to rely on manual CSV or Excel uploads in the first phase.

Step 4: Where does the data get stored?

Once a data collection strategy is established, the next challenge is data storage – how each product’s information will be gathered together under a digital profile called a Digital Product Passport.

In general, two options are being discussed for data storage for DPP. It’s unclear to what extend the storage will be regulated yet.

- Traditional cloud-based databases. These could provide information publicly to anyone, via APIs, as well as through different levels of access, depending on the stakeholder in the value chain.

- Blockchains (public and private). These can provide similar functionality to traditional cloud-based databases, as well as features which are unique to blockchains. Some industry players are advocating DPP as an ideal use case for blockchains.

Once all of the information is collected, and securely stored, the next step is to make this information available for your end users. You will need a data carrier on a product that end users can access, preferably with the resources they currently have.

Choosing the right data carrier for public disclosure (ie, QR code, NFC)

As per the emerging DPP regulations, a data carrier will be required at minimum at the batch level but likely also at the unit level for products. This data carrier must be secure and machine readable, while also providing transparency in that anyone can view the relevant product data on demand.

From the perspective of a manufacturer, the goal is to comply with DPP regulation and the need for data carriers on products in the most cost-effective way possible.

Let’s look at the three most widely used Data carriers and the pros and cons of each in the context of DPP.

Pros and cons of different data carriers for use with Digital Product Passports

| Data carrier | Description | Pros for use in DPP | Limitations for use in DPP |

|---|---|---|---|

| QR code (dynamic, serialized) | Small 2d code which can be scanned from any angle that can store thousands of characters. Dynamic QR codes have a redirect URL which can be changed anytime after application on the product, and where each QR code on each product has a unique identification number (ie, serial number) associated with it. | Can redirect a user to a DPP after scanning. Unit-level tracking. Cost effective, highly scalable. Ease of use, familiarity by consumers. Security features. | Requires digital printing or a hybrid printing setup. |

| NFC | An electronic tag or chip which doesn’t require a battery and is applied to the product which stores a unique identification number and can be scanned by NFC-supported smartphones. | Can redirect user to a DPP after scanning. Unit-level tracking. Security features | Significantly more expensive than printed options. Unfamiliar for many consumers. |

| Barcode | A traditional 1D barcode with a unique identification number stored in it. Can store dozens of characters and comes in many standards and sizes. | Unit-level tracking. Ease of printing. | Not scannable by consumers, so likely not compliant. |

| Serial number | A text, printed serial number that is unique from one product to the next. | Unit-level tracking. Ease of printing. | Only compliant if used alongside a URL to “look up” the DPP. Hard to scan in the value chain, may impact data collection. |

All things considered, QR codes stand out as Data carriers for DPP for their usability, familiarity, and cost-effectiveness.

Why QR codes for Digital Product Passports (DPP)

QR codes are one of the most promising tools for adopting Digital Product Passports. With a simple scan provides access to product information.

Not all QR codes are created equal though. Dynamic, serialized QR codes are required for creating effective Data carriers.

Static, non-serialized QR codes: Not suitable for DPP

Just like a barcode, a regular (static) QR code usually provides information on a specific product, but not down to the unit level. This makes them operable to identify models and batches, but not possible for use in unique product identification.

Dynamic, serialized QR codes: Ideal for DPP

However, by serializing QR codes (making each code unique), data can be associated to a specific product unit. This is a requirement for basic DPP requirements such as product traceability.

Furthermore, by making the target URL in the QR code dynamic (hence the term dynamic QR code), you have significantly more flexibility after the code is printed to change the post-scan experience and information displayed.

QR code security in the context of DPP

Most QR codes aren’t designed to be secure channels – they can easily be copied and printed on fake products, for example. However, secure QR codes can offer a high level of security; these QR codes contain a security image in the middle which, if the QR code is copied and used elsewhere, can be detected as a fake.

The main benefits of using QR codes as Data carriers for DPP use cases

- QR codes are user friendly – QR codes can be scanned with virtually any modern smartphone. Barcodes lack this ability, as they need special scanning equipment to perform scans for data. NFC tags are still new and consumers are becoming accustomed to them.

- QR codes are cost-efficient – QR codes are one of lowest-cost identifiers, especially for secure ones. QR codes integrate with your existing packaging or printing process unlike costly physical identifiers or security features like NFC.

- QR codes can be customized and changed in real-time – Dynamic QR codes can redirect users to customized landing pages, including ones containing Digital Product Passport information, which can be updated at any time.

- Scalability – Once the initial printing or labeling integration and testing are complete, the a secure QR code can be printed in a more scalable way compared to physically-applied unique identifiers.

At Scantrust we are excited about the future of transparency in how products are made and are dedicated to being a leading solution provider for Digital Product Passports. You can learn more about DPP regulation, implementation strategies, and our solutions by requesting a meeting with one of our solution experts.

Request a meeting with one of our solutions experts

During the meeting, one of our solutions experts will demonstrate the following:

- How Scantrust complies with Digital Product Passport regulations

- Why Scantrust stands out from other solutions

- Why QR codes are a great fit for digital product labeling

- How to integrate the Scantrust digital product labeling solution for your company

- A demonstration of our digital product labeling solution

Any questions you may have, we aim to answer.